Adding more value

to your operations

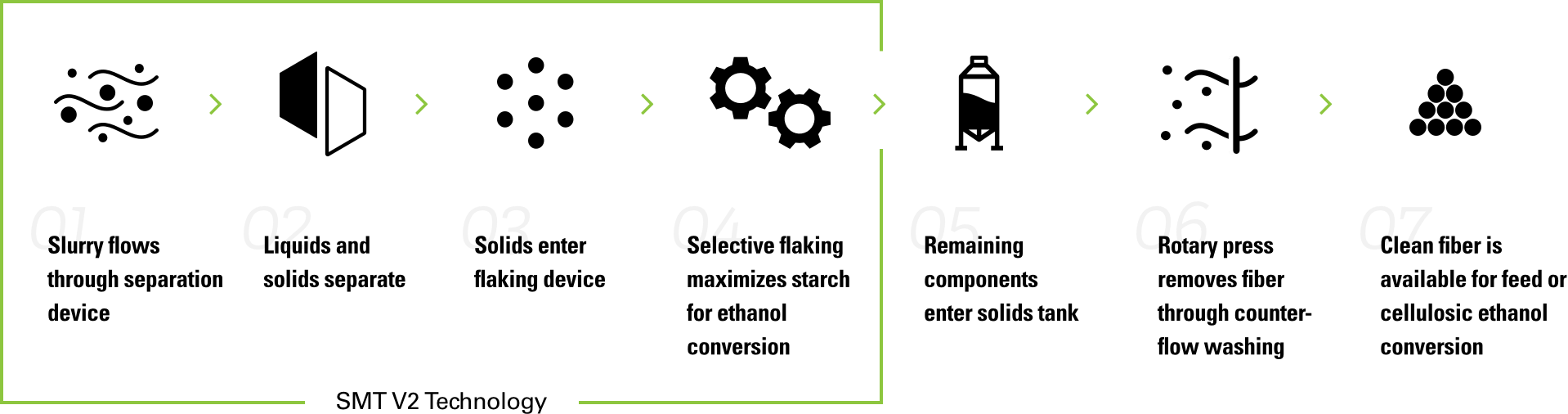

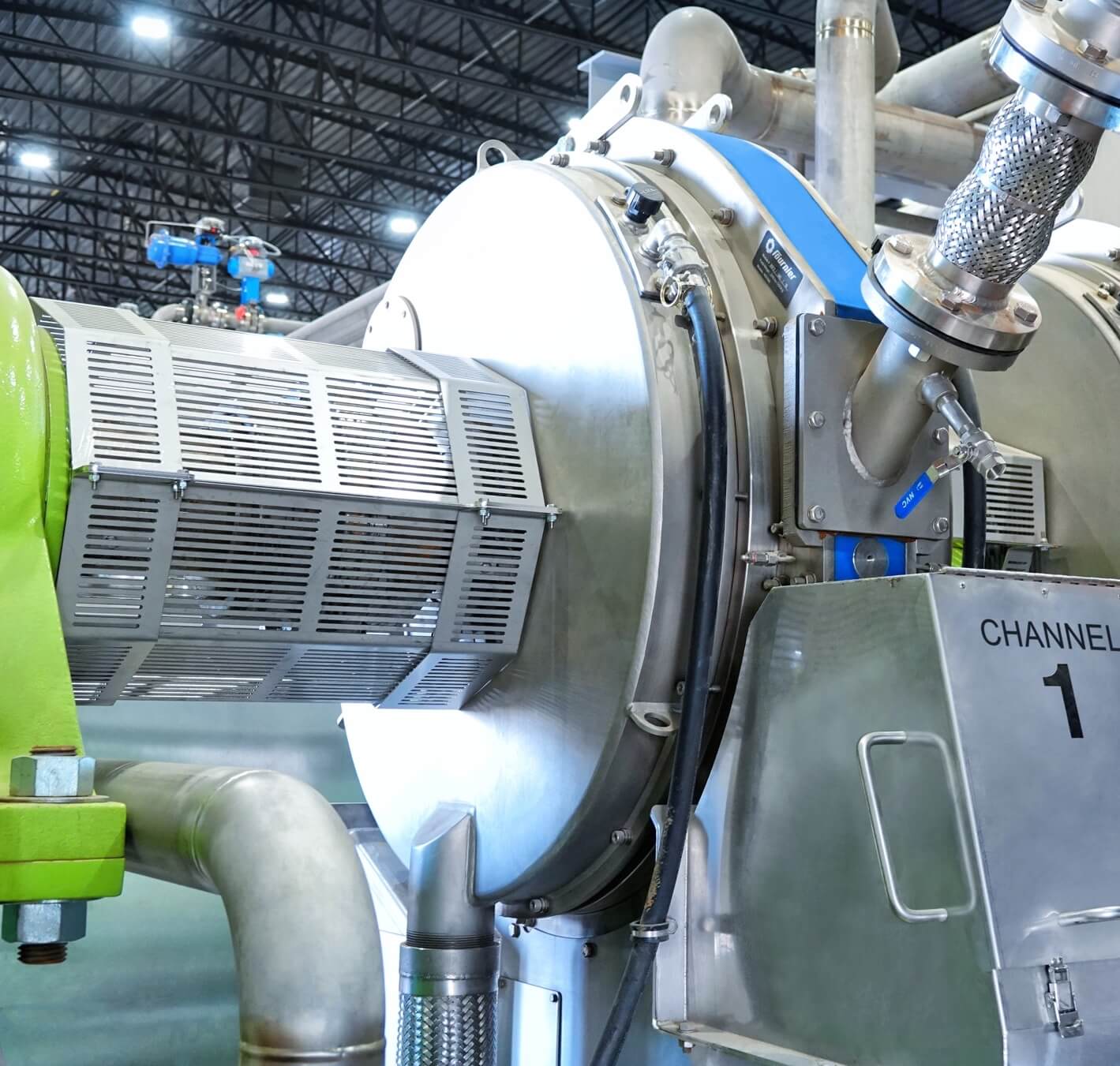

ICM’s patented FST™ and FST Next Gen™ technologies remove fiber on the front end of the process. Since fiber is removed before fermentation, your plant experiences less wear and tear on equipment, uses less energy in distillation and drying, requires fewer chemicals for cleaning and encounters fewer bottlenecks. All of this translates into operational savings that significantly contribute to your bottom line.

more

Without fiber, process streams contain higher concentrations of oil.

reduction

Compared to other offerings on the market, FST Next Gen™ saves more energy through higher processing efficiency and the removal of fiber prior to fermentation.

Fiber removal increases fermentation capacity.

FST™ and FST Next Gen™ give you the ability to make SOLBRAN™ animal feed and Hi-Pro DDG, a high-protein feed that sells at a significant premium over DDGS.

Learn more about adding value to your process with FST™ and FST Next Gen™.