In the early days of corn ethanol production, sufficient profit could be made by offering a simple mix of ethanol and distillers dried grains (DDG). This strategy allowed a plant to focus on ethanol yield, which was sufficient for most plants’ bottom line.

In today’s climate, a variety of factors have made it more challenging for plants to profit using traditional production methods. To achieve growth, plants must focus on product diversification and creating operational efficiencies, both of which can be realized by implementing a more effective corn separation process.

Increasingly, the key to creating sustainable business for ethanol producers is to diversify corn-derived products and therefore, revenue streams. As the demand for protein increases worldwide, meeting that need requires greater availability of feed protein products for the meat animals we consume. Traditionally, one cost effective source of protein has been distillers dried grains (DDG) used in feeding swine, poultry, and beef and dairy cattle. However, traditional production processes result in imperfect composition of the DDG, yielding residual component levels that reduce the efficacy of the target components, especially protein.

Corn has four significant components – starch, protein, fat and fiber – but yields only three products: ethanol, corn oil and DDG. With only three buckets in which to put corn components, DDG is left as a mixture of the remaining materials which leads to too much protein for ruminant diets. The high fiber content of DDG prevents its expansive application to non-ruminant feeds, where the value of the protein is several factors higher. This makes the animal feed production fraction of a standard corn ethanol plant a prime spot for better separation processes.

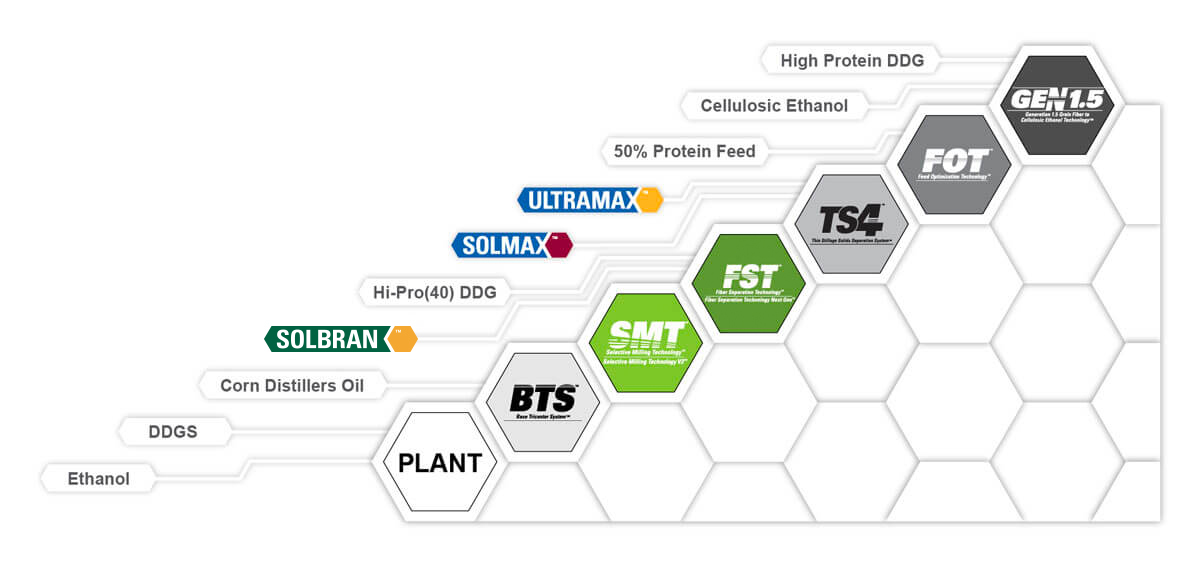

ICM has a long history of providing solutions focused on improving operations and opening up opportunities to create higher value products. In just the past decade, ICM has developed several technologies designed to improve the corn separation process, including Base Tricanter System™ (BTS™), Selective Milling Technology™ (SMT™) and Selective Milling Technology V2™ (SMTv2™), Fiber Separation Technology™ (FST™) and Fiber Separation Technology Next Gen™ (FST Next Gen™), Thin Stillage Solids Separation System™ (TS4™), and Fiber Optimization Technology™ (FOT™). See Figure 1.

ICM’s patented FST™ and patented FST Next Gen™ remove fiber from the corn kernel, prior to fermentation. The clean fiber stream remaining after these separations becomes available as feedstock for ICM’s patent-pending Gen 1.5 process. Traditionally, the fiber has value in DDG, but when separated into its own stream, the fiber becomes available for conversion to cellulosic sugars for ethanol production. The fiber-stripped residual solids then become a higher value, high-protein DDG.

Figure 1. ICM’s Platform Technologies and Feed Products

Corn has two fiber fractions: the pericarp is the thin bran layer covering the outside of the kernel consisting primarily of lignocellulose and the tip cap which is a fibrous particle where the corn was at one time attached to the cob with less lignocellulose and higher protein and fat content. Both are prime feedstock for ICM Gen 1.5 process.

Collectively, ICM’s proprietary technologies increase the number of streams from the ethanol plant, allowing for higher purity products with elevated application and value. Most notably is its patent-pending Grain Fiber to Cellulosic Ethanol Technology™ (ICM Gen 1.5), which captures a significantly higher RIN value than normal high efficiency starch ethanol and produces a high-protein DDG.

In recent years, prolonged struggles at pioneer second-generation ethanol plants have cast a shadow over use of lignocellulose as a feedstock for fuel ethanol. In 2017, the Department of Energy initiated the Feedstock-Conversion Interface Consortium (FCIC), aimed at improving the reliability of the frontend delivery of the biomass (primarily focused on agricultural residues and woody feedstocks) to the reactor throat. These challenges have yet to be solved, and as a result the industry perceives large-scale cellulosic ethanol as a high technical risk.

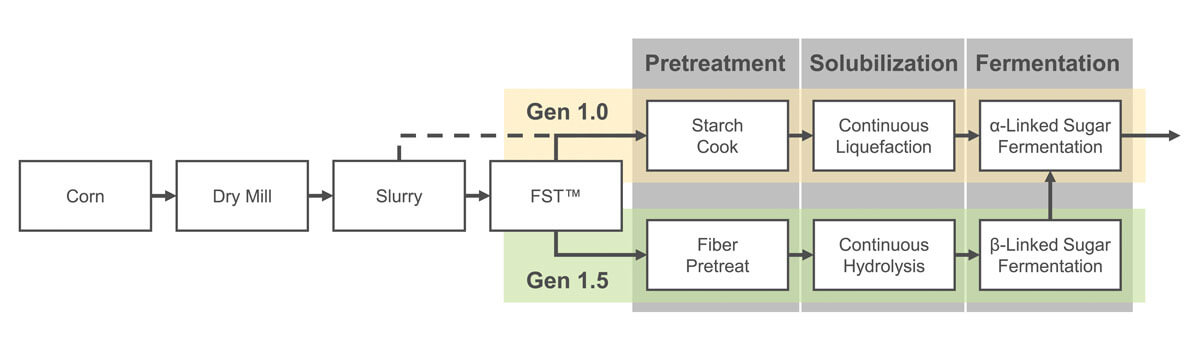

ICM’s Gen 1.5 cellulosic ethanol is different from other cellulosic ethanol processes. ICM approached cellulosic ethanol with the understanding that it could be made in a very similar manner as Generation 1.0 starch ethanol (Gen 1.0). Both processes have similar feedstock pretreatment, solubilization and fermentation steps, customized to each carbohydrate structure. See Figure 2.

Figure 2. ICM’s Gen 1.5 is Similar to Gen 1.0

With both starch and fiber, the feedstocks have to be treated to open up the structures to get greater enzyme accessibility. In the starch process, this can be done with elevated cook temperatures; with fiber, temperatures need to be higher and the process is most efficient with use of an acid or base catalyst. In the ICM Gen 1.5 process, sulfuric acid is added during this pretreatment step, providing a secondary value from the same chemical used to reduce pH in the starch ethanol production and eliminating the need to add it later.

Both starch and fiber processes need to convert the carbohydrate polymers into fermentable monomeric sugars through the use of enzymes, with specificity to the sugar chain bonds of each feedstock. Although the fiber is cleaned with hot water in the patented FST™ process, some highly bound recalcitrant protein, starch and fat can remain attached to the fiber. In the Gen 1.0 ethanol process, these components would pass to the backend of the process and end up as low digestible protein and residual starch in the DDG. Instead, in the ICM Gen 1.5 process, pretreatment partially hydrolyzes the components, making them easier to ferment to ethanol and become more digestible animal protein.

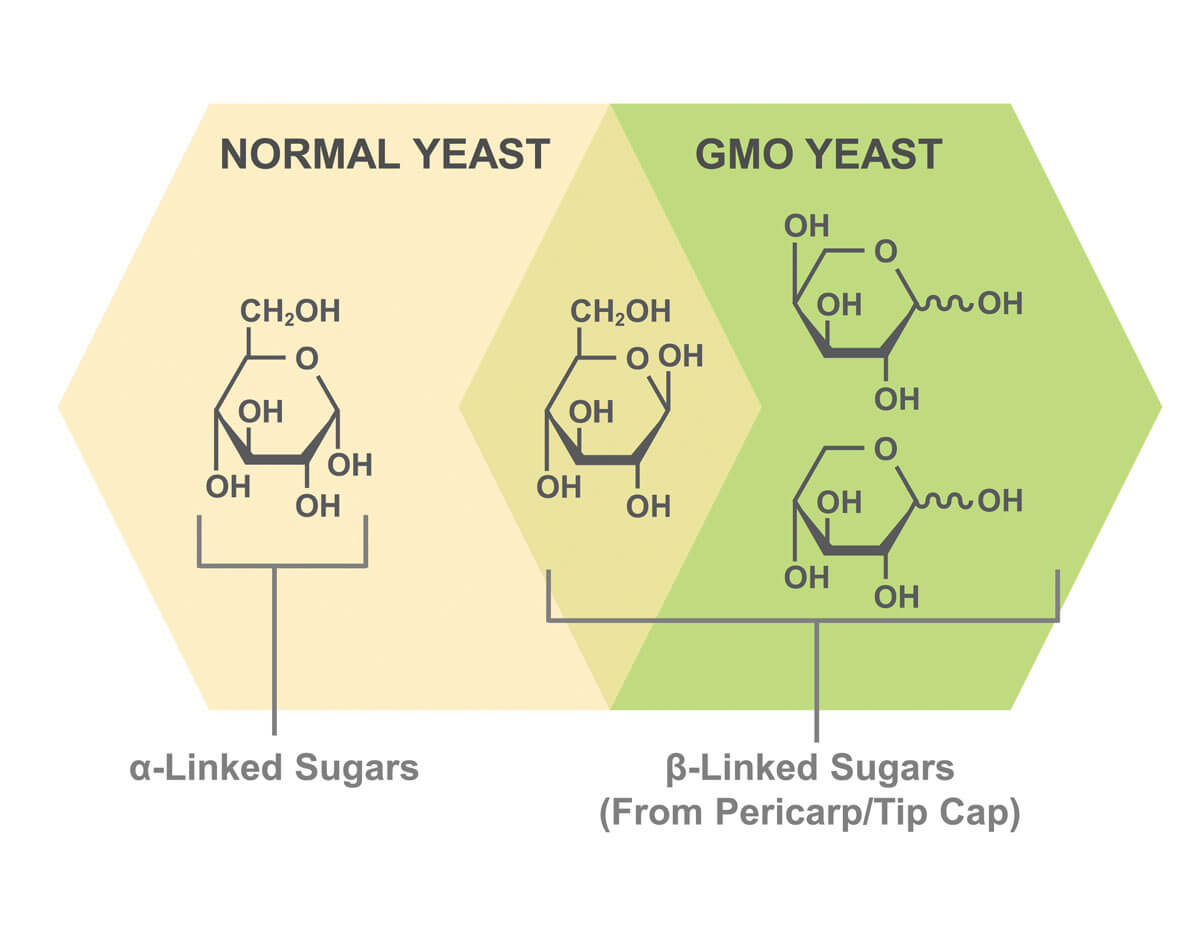

In the ICM Gen 1.5 process, fermentation is achieved using a specially designed GMO yeast developed to ferment not just the glucose, but also the five-carbon (C5) xylose and arabinose sugars present in the corn kernel fiber. See Figure 3. The fermentation itself is nearly identical to starch ethanol production, but accessing the xylose and arabinose sugars nearly triples the amount of cellulosic ethanol that can be made. It is of utmost importance to use the C5 yeast for corn kernel fiber ethanol: without the yeast metabolizing the elevated levels of arabinose, lactobacillus will convert the valuable sugars into suboptimal lactic acid.

Figure 3. ICM Uses a Special GMO Yeast that can Ferment all the Sugars

Due to flowability limitations of fiber slurries prior to pretreatment and solubilization, the sugar content of the fiber sugars may be only 5-7% ethanol by weight. Processing yield and capital cost advantages are attained by including the Gen 1.5 beer in the fill of the five times larger starch ethanol fermentation process. This allows the ICM Gen 1.5 process to provide a 10% ethanol yield gain to the plant, instead of only the 7% that would be obtained from processing the Gen 1.5 fiber beer separately, and saves a significant amount of capital cost on the backend of the plant because the same decanter, distillation and dehydration systems are reused.

The ICM Gen 1.5 process is designed as a bolt-on lignocellulosic technology with a small footprint. ICM focused on making the process simple by keeping the flows pumpable and the fermentations operationally standard. The result is three unit operations similar to present starch ethanol processes, at a scale where facilities can learn to efficiently operate second generation feedstock processing without addition of problematic new feedstock handling and logistics systems, nor difficult pretreatment feedstocks with high levels of lignin and extractives.

Western-facing ethanol plants utilizing the ICM Gen 1.5 processes can also realize a very significant additional value from Low Carbon Fuel Standard programs. Carbon intensity (CI) is creating a growing demand for cellulosic ethanol and ICM’s Gen1.5 process gives an ethanol stream with a CI score in the single digits. This has the potential to increase the profitability of all gallons from a starch ethanol plant by 20 to 30 cents per gallon. In this way, the lowest value fiber stream in an existing plant has become the highest value product.

In the future, sustainability at an ethanol plant will become increasingly dependent upon its ability to increase product diversity, which can be achieved by careful consideration of how to maximize both purity and volume of higher value products. With its Gen 1.5 process, ICM has developed a method for processing high volumes of low value corn fiber into premium products with high demand, utilizing processing methods similar to unit operations familiar to starch to ethanol producers.